|

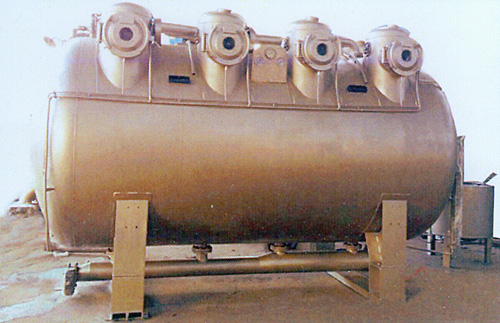

OH系列高温溢流染色机

OH High-temperature Overflow Dyeing Machine

UH系列常温溢流染色机

UH Normal-temperature Overflow Dyeing Machine

优越性能

●适应布种范围广:

特别喷嘴结构,使织物一直处于松懈展幅状态。针对解决密度大、易生折痕及敏感色等织物的染色问题。

●节能省时,配合各项新技术:

1、立式热交换器,高效而美观的布置,能及时排净冷凝水及染液,缩短冷热转换消耗时间,同时避免水垢形成,延长交换器使用寿命,减少时间和能源。

2、自动刮毛器与粹毛收集器合为一体既节省安装位置又减少染液。减少人工刮毛所消耗时间。

3、优化主泵进口管道,使吸口更低,用水更少。

4、U型布槽加十字摆布方式,比同样机型之染缸装载量增加20%,降低了成本。

5、独创喷嘴导布管洗水功能,缩小洗水时间及用水量。

●环保

最低行机浴比低至1:1.5(不包括织物含水)纯棉活性染料染色全程每公斤织物耗水量约为:浅色27.2公斤;中色37.5公升;深色47.4公升。

●稳定的高重现性

超前的染色控制系统,配合双重均衡加料系统,衡压与衡流量喷嘴控制,使织物染色达到良好的均染性和重现性。

●人体工学缸身设计

降低机身与操作高度,放弃巨型工作台,操作方便,独特缸底设计能有效减少储水,降低浴比。

●独特的主缸循环系统使主缸上下温差控制与加料的均匀性控制在最佳状态。

●主缸清洗采用旋转喷射方式,缸身全方位都在清洗范围内,缸身清洗更彻底。

Excellent Performance

●Application to various fabrics

With a spcially-designed nozzle structure,it enables the fabrics in loose and expanded conditions during the dyeing process.It has an excellent performance in deing tight and heavy fabrics and can eliminate the crease mark problem,which is usually seen in other dyeing machines.

●Time and energy saving by using new technologies

1.The nice and efficient configuration which is built with a vertical heat exchanger enables the condensed water to be drained instantly and reduces the time duration in the shifting between hot and cold water.Meanwhile,it can avoid the formation of water scale,extend the service life of heat exchanger,and reduce time and energy as well.

2.The intergration of automatic stripper and lint collector can save installation space,economize dye liquid and reduce the manual stripping time greatly.

3.The inlet pipe of the main pump has been optimized,the height of water inlet has been lowered and hence the water consumption has been reduced sighificantly.

4.Compared with other designs,U-shape fabric tank and cross configuration of this new model can increase the loading capacity by 20%,up ti 300kgs per chamber approximately.

5.Unique fabric flowing tube with nozzle can reduce washing time and water consumption.

●Eco-friendly

Min running liquor ratio(does not invlude water in the material)is as low as 1:1.5.The water consumption of the whole dyeing processfor cotton fabric(per KG)by using reactive dyes is analyzed as follows.

Light Color:27.2kgs

Medium Color:37.5kgs

Dark color:47.4kgs

●Good and stable repeatability

Leading dyeing control system,in combination with dually balancing flow feeding system as well as constant pressure and flow rate nozzle control enbance fabrics dyeing to achieve a good dye uniformity and high repeatability.

●Ergonomics Vat Design

The height of machine and operation platform is lowered and size of the operation platform is resized much smaller than usual,which makes operation much more convenient.The bottom of the dye vat is specially designed so as to reduce water storage and liquor ratio effectively

●With unique main vat circulation system,the temperature difference of entire dye vat from top to bottom and evenness of feeding is controlled at optimum conditions.

●Rotating spray is adopted for main vat cleaning and the whole vat is within the range of cleaning,ensuring more complete cleaning.

任选件

●预备缸可选配置,可使工作效率提高。

●注盐桶,新式注盐功能,注盐更快更顺畅。

●自动刮毛器与粹毛收集器合为一体及节省安装位置及减少染液。减轻人工刮毛所消耗时间。

Optional Parts

●The optional configuration of multi-functional stock tank can improve working efficiency greatly.

●Salt addition tanks are of new filling functions,enstring quicker and smoother filling.

●The intergration of automatic stripper and lint collector can save installation space,economize dye liquid and shorten the manual strpping time.

技术数据

●浴比:满载时1:4-5

●运行速度:400米/分钟

●最高工作温度:140℃

●最高工作压力:0.36Mpa

●升温率:25℃-100℃平均5℃/分钟

100℃-130℃平均2.5℃/分钟(干燥饱和蒸汽压力0.7Mpa)

●降温率:130℃-100℃平均3℃/分钟

100℃-85℃平均2℃/分钟(冷却水压力0.3Mpa,温度25℃)

Technical Data

●Liquor Ratio;1:4-6 at full load

●Operating Speed:400M per minute

●Maximum working temperature:140℃

●Maximum working pressure:0.36Mpa

●Temperature increase rate:5℃ per minute on average from 25℃ to 100℃,2.5℃ per minute on average from 100℃-130℃(Pressure of dry saturated vapor:0.7Mpa)

●Temperature deduvtion rate:3℃ per minute on average from 130℃ to 100℃,2℃ per minute on average from 100℃ to 85℃(Cooling water pressure:0.3Mpa,25℃)

OH系列高温溢流染色机机械参数

OH High-temperature Overflow Dyeing Machine and mechanical parameters

|

型号

Model |

管数

Number of tubes |

载量

Load(kg) |

主泵功率

Power |

外形尺寸(长×宽×高)

Outer Dimension |

|

OH-250-1 |

1 |

300 |

5.5 |

3500×5400×3200 |

|

OH-250-2 |

2 |

600 |

7.5 |

4800×5400×3400 |

|

OH-250-3 |

3 |

900 |

15 |

5900×5400×3400 |

|

OH-250-4 |

4 |

1200 |

18.5 |

7100×5400×3400 |

|

OH-250-6 |

6 |

1800 |

30 |

9500×5400×3400 |

|

OH-250-8 |

8 |

2400 |

45 |

12500×5400×3400 |

所列规格如有改良或修正,不再另行通知。

Specification subject to change without further notice

UH系列常温溢流染色机机械参数

UH Normal-temperature Overflow Dyeing Machine and mechanical parameters

|

型号

Model |

管数

Number of tubes |

载量

Load(kg) |

主泵功率

Power |

外形尺寸(长×宽×高)

Outer Dimension |

|

UH-250-1 |

1 |

300 |

5.5 |

3500×5400×3200 |

|

UH -250-2 |

2 |

600 |

7.5 |

4800×5400×3400 |

|

UH -250-3 |

3 |

900 |

15 |

5900×5400×3400 |

|

UH -250-4 |

4 |

1200 |

18.5 |

7100×5400×3400 |

|

UH -250-6 |

6 |

1800 |

30 |

9500×5400×3400 |

|

UH -250-8 |

8 |

2400 |

45 |

12500×5400×3400 |

所列规格如有改良或修正,不再另行通知。

Specification subject to change without further notice

|