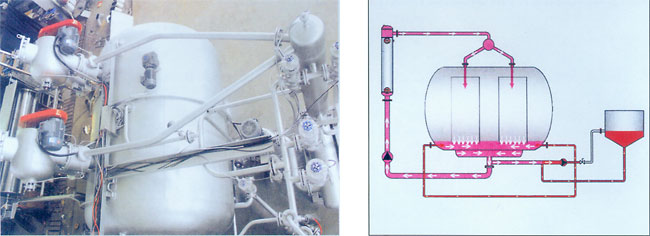

SX215 SERIES ENVIRONMENT-FRIENDLY DYEING MACHINE

产品优点:

SX21 5系列环保型染机是晟翔机械推出的一种高节能环保型染色机,该机保持了溢流染色机基本原理 但浴比低至1: 4-1: 4.5,同时水洗效果也极高,相比传统染机总耗水量大大减少升温蒸汽也大大节约, 可称得上是集省电、省水、省蒸汽于一体的新一代低碳染机。

Advantages :

Environment-friendly SX215 Series Dyeing Machine is an energy—saving and environment-friendly dyeing machine launched by Shengxiang Machinery. This machine keeps basic principle of overflow dyeing machine, but its bath ratio is 1:4〜1:4.5. And it has good washing effect. Compared with traditional dyeing machine, total water consumption has been greatly reduced. Heating steam has been also greatly saved. It can be called the new generation of electricitysaving, water-saving, and steam saving lowarbon dyeing machine.

SX215系列环保型染机针对不同染物的需要,通过伺服驱动系统来精确控制喷嘴的流量。

SX215 Series Environment-friendly Dyeing Machine can satisfy different dyeing needs. Nozzle flow is eacc-urately controlled through the servo driving system.

为确保染机各喷嘴系统在染色过程中压力及流量的匀衡性,根据由集管箱统一分流的匀衡性输送原理, SX21 5系列环棟型染机采用了集液单独分路输送系统,以减小每个喷嘴间的输液差异。

To ensure pressure and flow balance of each nozzle system in dyeing machine in the process of dyeing, according to balanced delivering principle in which junction box uniformly distributes, SX21 5 Series Environment-friendly Dyeing Machine uses separate collecting liquid shunting conveying system, to reduce the differences between liquid delivering of each nozzle.

均匀的回流和横向循环是SX21 5系列染机的又一个主要创新技术,部分染液通过横向循环系统的双向循环 作用,增加了染液与织物的交换次数,极大提高了染色处理染液速度,进而也就提高了染液的混合与匀染效果。

Uniform backflow and transverse cycle is another major innovative technology of SX21 5 Series Dyeing Machine. Bidirectional circulatory function of transverse circulatory system increases exchange times of dye liquor and fabric, significantly increases processing speed of dye liquor, and improves mixing and leveling effect of dye liquor.

为更好的提高SX215系列环保型染机生产的 适用普遍性,SX215系列环保型染机在传统双化 料筒的基础上,设置了预备缸,进而解决了化料 筒容积小的冋题。

In order to improve its suitability and universa¬lity in production, SX21 5 Series Environment- friendly Dyeing Machine adds preparation cyli-nder on the basis of traditional double dye tube, so as to solve the problem of small volume of feed cylinder.

|